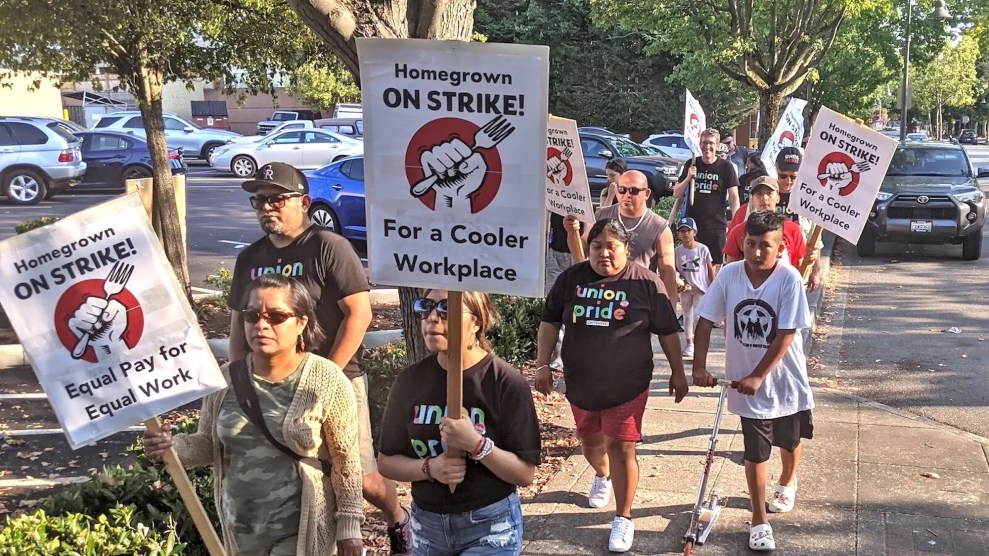

Maria Leon went to the hospital after exposure to workplace chemicals.Teamsters

If you’ve ever purchased pre-cut produce at Costco or Safeway, or eaten at fast-food restaurants such as McDonalds or Chipotle, chances are that your food was handled by workers at Taylor Farms. As one of the world’s largest fresh-cut produce companies, it employs hundreds of low-wage workers in several warehouses in and around California’s Central Valley. These are the people who dice the lettuce in your burger and mince the cilantro in your burrito.

Fresh-cut produce suppliers allow restaurant chains to reduce labor costs and ensure that their foods are prepared under sterile conditions. In response to E. coli outbreaks in 2015, Chipotle announced that it would stop dicing tomatoes in its restaurants; like many other fast-food chains, it now sources some of that prep work from Taylor Farms.

But these massive warehouses carry risks of their own. To prevent E. coli and salmonella outbreaks, fresh-cut produce firms treat their vegetables with chlorine and use other cleaning chemicals that sometimes can pose hazards to workers.

Since 2012, two separate chemical accidents at a Taylor Farms plant in California have sent some 40 workers to the hospital. During that time, California’s Occupational Safety and Health Administration issued the company 55 violations and fined it more than $100,000 for problems that included failure to monitor workers’ chemical exposures, failure to notify workers of what they may be exposed to on the job, and failure to train workers properly. Inspectors found that Taylor Farms repeatedly “failed to control production area employee exposure to chlorine so as to prevent harmful effects such as significant eye, nose, and lung irritation, vomiting, nose bleeds, and fainting.” Taylor Farms is contesting these violations and many of the others.

Partly in response to the persistent safety problems, workers at Taylor Farms’ plant in Tracy are trying to unionize. But the company has fought back aggressively. The National Labor Relations Board filed a complaint against Taylor Farms, citing dozens of alleged violations of federal labor law, including spying on, threatening, and firing pro-union workers. (The company and its contractors, without admitting fault, settled the case for $267,000.)

Last August, Taylor Farms workers protested outside Albertsons grocery stories, holding signs that said, “Taylor Farms Makes Bad Salads.” A group of workers from the Tracy plant also traveled to San Francisco to hold a protest outside a Chipotle restaurant. Among them was Maria Leon, then a 32-year-old mother of four who worked chopping vegetables. Leon, who was pregnant at the time of the incident, told me the following story, which I’ve corroborated with other workers and edited for length and clarity:

I work at a conveyor belt—they call it the prep line. The vegetables arrive whole. We cut the bell peppers in half and take out the seeds. We take the rubber bands off of cilantro and green onions. We take off the roots, we take off the tips. We cut them and we pack them. For all of this we just use knives.

It’s very cold—like 33 or 34 degrees. To stay warm, we wear three or four sweaters or very heavy coats. The broccoli and green lettuce comes packed in ice and we have to take it out. We put on three gloves, one of plastic, one of fabric, and one made of metal. But it’s still cold.

They use the chemicals in the water to sterilize the vegetables and to wash the machines. The air everywhere in the plant has the smell. This is one of the worst things about the job. There’s one chemical that reacts with our eyes. They don’t use it on the prep line, but they do use it in other areas where practically every day people come into contact with it.

On October 15, I punched in and entered the production room where I work. I smelled a very strong odor. I arrived at my line and told the crew leader, “I’m going to leave.” I went across the room. About four minutes later, he came over and suggested that I try wearing a paper mask and return to the line. Because I was pregnant, I’d sometimes had nausea and vomiting, so I didn’t know if that was why I was feeling bad. So I put on the mask and I went to work.

It bothered me to go in there. It hurt too much. But none of my coworkers were saying anything. Then people started getting sick. After about 10 minutes, a crew leader opened a door and said, “Please go outside. Go outside.”

There weren’t alarms that sounded, they didn’t say leave immediately. The only people who even remotely knew what was going on were the crew leaders, who carry radios with earpieces. The crew leaders told people what to do, but there were many people who couldn’t hear them, who work alone. In the beginning, they had no way to know that it was an emergency and they should leave.

I felt dizzy and nauseous. Others were coughing. Others had blood coming out of their noses. It was maybe 25 minutes before the ambulances arrived.

The paramedics told me I had too many chemicals on me and they took off all my clothes. When I arrived at the hospital, the doctors ordered me to bathe. They washed me off because they said I smelled too strongly of chemicals. I think they did this as a precaution because I was pregnant.

I asked the doctor about my baby. We still don’t know what will happen. I did the studies with the doctor and everything is fine up until now, but she could develop asthma or respiratory problems. I hope nothing will happen. [Update: The baby was born healthy and so far hasn’t experienced any significant problems.]

I don’t know much about the chemicals they use. I’m not responsible for that. Sometimes the odor is a little stronger, sometimes it’s less. People are afraid of breathing it, but they don’t protest. They will say you don’t have papers. That’s what the workers think. Everybody is afraid.

People often ask me, “What are you doing there?” But I need to work because I am a single mother. I have three other girls: eight, nine, and 13 years old.

We don’t have set hours. My line begins at 5:20 a.m. We could be finished at one, or at three, or at five. There’s no normal day. If they want to, they can keep you for more than 12 hours.

Right now they pay $10.50 an hour, 50 cents more than minimum wage. It depends on the hours, but in a typical week we might make $470. It’s difficult at this wage. It’s good that the father of my children is helping me with the girls, because otherwise what I earn at Taylor wouldn’t be enough.

I don’t think people who shop at Chipotle or Costco would do so if they knew what was going on. The working people, at this wage, they say what does it matter if the product goes out well? If you don’t take an interest in us, then we could care less about you.

If we had a union, maybe they would pay us better and create a plan so that we aren’t breathing chemicals. We hope that they can stop thinking of us like we are machines. The chemicals don’t hurt the machines but they do hurt us. Machines can work without a decent wage, but we can’t.

Respect above all is what we need.

Contacted by Mother Jones, Taylor Farms owner Bruce Taylor said that his company had officially contested the OSHA and NLRB citations. He also disputed many of Leon’s claims. The company’s third-party consultant routinely tests air quality inside the plant and hasn’t found any problems, he said, and the level of chemical exposure resulting from the October accident was akin to what you’d get from “swimming in your swimming pool.” (The OSHA documents suggest otherwise.) Taylor said Leon’s claims about being pressured to work on the day of the accident “were thoroughly investigated and determined to be baseless,” and he insisted that crew leaders did a good job communicating the need to evacuate. (Citing OSHA appeals, he would not provide immediate access to the company’s consultant or paperwork from its internal investigation.) The plant has an alarm for chemical spills, he said, and its overall safety record is above average, with no lost time or injuries since the beginning of the year.

The typical entry-level Taylor Farms worker makes $25,000 to $35,000 a year, Taylor said. Overtime is voluntary: “We have a great relationship with our people, and we try to make sure we take care of them.” The Chipotle protest, he added, was simply an effort to “blackmail” his company into signing a union deal.